ISSN:1692-7273 | eISSN:2145-4507

Measuring Back Injury Risk in Mexican Workers of an Automotive Company

Medición del riesgo de lesión de espaldaen trabajadores mexicanos de unaempresa automotriz

Medição do risco de lesão de costas em trabalhadores mexicanos de uma empresa automotiva

Luis Cuautle-Gutiérrez, María Teresa Escobedo-Portillo, Luis Alberto Uribe-Pacheco, José Domingo García-Tepox

Measuring Back Injury Risk in Mexican Workers of an Automotive Company

Revista Ciencias de la Salud, vol. 17, no. 2, 2019

Universidad del Rosario

Luis Cuautle-Gutiérrez luis.cuautle@upaep.mx

Universidad Popular Autónoma del Estado de Puebla, México

María Teresa Escobedo-Portillo

Autonomous University of Ciudad Juárez, México

Luis Alberto Uribe-Pacheco

Universidad Popular Autónoma del Estado de Puebla, México

José Domingo García-Tepox

Universidad Popular Autónoma del Estado de Puebla, México

Received: 13 November 2018

Accepted: 11 April 2019

Additional information

To cite this article: Cuautle-Gutiérrez L, Escobedo-Portillo MT, Uribe-Pacheco LA, García-Tepox JD. Measuring back injury risk in Mexican workers of an automotive company. Rev Cienc Salud. 2019;17(1):175-87. Doi: https://doi.org/10.12804/revistas.urosario.edu.co/revsalud/a.7921

Abstract: Introduction: The Mexican manufacturing sector in the automotive industry employs an average of 8 million 850 thousand workers per year spread across the 32 states, of which Puebla contributes with 465 106, developing, in a high percentage, the verification of new parts as part of the manufacture process. This activity is supported by the use of devices known as fixtures, whose equipment and tool forces operators to lift loads between 10 and 50 kilograms by performing manual operations to hold parts, presenting pain at the lumbar level, therefore, it is essential to measure the risks of back injuries in the study population. The objective was to identify and measure the risks of back injuries in the study population. Materials and Methods: The inspection process is analyzed by identifying the potential risk factors. Ergonomic methodologies and instruments are used, such as Quick Exposure Check (qec), the National Institute for Occupational Safety and Health (niosh) equation, the reba (Rapid Entire Body Assessment) method, Ovako’s Work Posture Analysis System (owas), among others. Results: The qec method shows that trunk/back and wrist/hand are the most sensitive parts to risk exposure, indicating that 18 % of the postures are rated 4 in the level of risk, with the back rotated and bent in over 32 % of time. The weight of the operation exceeds 20 kilograms in 71.4 %. Conclusion: Four ergonomic techniques are used to assess the risk of injury, the inspection process of manufactured parts is analyzed.

Keywords Ergonomics, risk control, quality inspection.

Resumen: Introducción: la industria manufacturera mexicana del ramo automotor emplea en promedio 8 millones 850 mil trabajadores al año repartidos en los 32 estados, de los cuales Puebla contribuye con 465 106, desarrollando, en un alto porcentaje, la verificación de piezas nuevas como parte de los procesos de manufactura. Esta actividad se apoya en el uso de dispositivos conocidos como fixtures, cuyo equipo y herramienta obliga a los operarios a levantar cargas entre los 10 y los 50 kilogramos, realizando operaciones manuales para la sujeción de piezas, presentándose dolores a nivel lumbar, por lo que es primordial medir los riesgos de lesiones en la espalda de la población en estudio. El objetivo fue identificar y medir los riesgos de lesiones en la espalda de la población en estudio. Materiales y métodos: se analiza el proceso de inspección identificando los factores de riesgo potencial. Se utilizan metodologías y herramientas ergonómicas, tales como Quick Exposure Check (qec), la ecuación del National Institute for Occupational Safety and Health (niosh), el método reba (Rapid Entire Body Assessment), el sistema de análisis de posturas de trabajo de Ovako (owas), entre otras. Resultados: el método qec muestra que tronco/espalda y muñeca/mano son las partes más sensibles a la exposición de riesgo, señalando el 18 % de las posturas en un nivel de riesgo 4, con la espalda rotada y flexionada en más del 32 % del tiempo. El peso que conlleva la operación supera los 20 kilogramos en el 71,4%. Conclusión: se utilizan cuatro técnicas ergonómicas para evaluar el riesgo de lesión y se analiza el proceso de inspección de piezas fabricadas.

Palabras clave: ergonomía, control de riesgo, inspección de la calidad.

Resumo: Introdução: a indústria manufatureira mexicana do ramo automotivo emprega em média 8 milhões 850 mil trabalhadores ao ano repartidos nos 32 estados, dos quais Puebla contribui com 465 106 deles, desenvolvendo, em uma alta porcentagem a verificação de peças novas como parte dos processos de manufatura. Esta atividade apoia-se no uso de dispositivos conhecidos como fixtures, cuja equipe e ferramentas abriga aos operários a levantar cargas entre os 10 e 50 quilogramas realizando operações manuais para a fixação de peças, se apresentando dores no nível lombar, pelo que é primordial medir os riscos de lesões nas costas da população em estudo. Materiais e métodos: se analisa o processo de inspeção identificando os fatores de risco potencial. Se utilizam metodologias e ferramentas ergonómicas, tais como Quick Exposure Check (qec), a equação do National Institute for Occupational Safety and Health (niosh), o método reba (Rapid Entire Body Assessment), o sistema de análise de posturas de trabalho de Ovako (owas), entre outras. Resultados: o método qec mostra que o torso/costas e o pulso/mão são as partes mais sensíveis à exposição de risco, assinalando o 18 % das posturas em um nível de risco 4, com as costas rotadas e curvadas em mais do 32 % do tempo. O peso que leva a operação supera os 20 quilogramas no 71.4 %. Conclusão: utilizam-se quatro técnicas ergonómicas para avaliar o risco de lesão e se analisa o processo de inspeção de peças fabricadas.

Palavras-chave: ergonomia, controle de risco, inspeção da qualidade.

Introduction

The Mexican Secretary of Labor and Social Prevision reports that in the first quarter of 2018 in Mexico, 8 850 675 persons were employed in the manufacturing industry (1). Of this total, men represent 62.9 %, while women the remaining 37.1 %. For its part, the state of Puebla contributes with 465 106 persons in this sector.

In industrial terms, the main manual activities include lifting, placing and manipulating different objects (2). An example of this is represented in quality inspections. These inspections are characterized by work execution times and presence of repetitive movements, which can trigger discomfort, pain or injuries in workers.

In the manufacturing processes, it is an ordinary activity to check workpieces and/or assemblages in order to find defective items. Generally, this activity is carried out with the help of devices known as fixtures. A fixture allows to firmly hold a workpiece in a desired position and direction. Its typical structure is composed of a base plate and different types of gripping and positioning units connected to it (3).

For its part, ergonomics has developed various methods for risk analysis, among the quick exposure check (qec). This method was developed by the Surrey University, in Great Britain, and is used to assess the exposure to muscle-skeletal disorders associated to work, for back, shoulder/arm, wrist/hand and neck. In its implementation, a verification sheet for registering information on working hours, maximum weight put on the wrist, hand strain, vibration and visual demand is used. Afterwards, collected information is compared with the results of the qec (4). 1981, the National Institute for Occupational Security and Health (niosh) published guidelines related to hand lifting, and developed a load lifting equation. The latter allows establishing safe load limits and assessing risks during this kind of tasks, thus achieving the reduction of the possibility of pain or back injury (5).

On the other hand, the Rapid Entire Body Assessment (reba) method assesses risk of exposure associated with musculoskeletal disorders based on the worker’s posture when performing his/her task. Through observation, following body parts are highlighted: trunk, neck, legs, arms and wrists. Likewise, it includes requirements of strength/loads, object attaching and an activity score (6, 7).

Finally, the Ovako Working Posture Analysis System (owas) determines the load related to posture and the potential injury connected to back and lower back. Its implementation is based on a work sampling that provides frequency and timing of each posture (8, 9).

Materials and Methods

The study was carried out in a Mexican manufacturing company of the automotive sector located in the city of Puebla, Mexico. A quality inspection process was selected due to the constant back discomfort in workers of this activity; through video records of the operations as they develop in the work environment the performed movements could be observed. Additionally, various ergonomic methods were implemented in order to identify the existing ergonomic risks.

Operation Analysis in the Workstation

Within a week and in eight-hour workdays, observation and video-recording of the workers performing their daily activities were conducted and for assessing the possible ergonomic risks the performance of these activities implies.

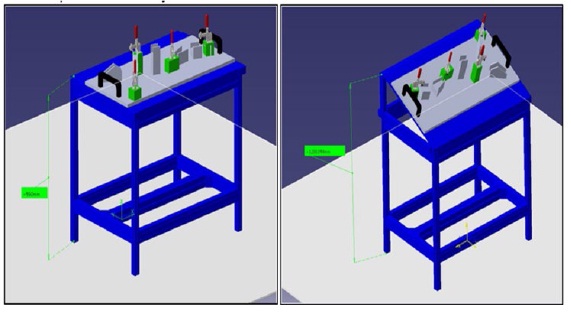

The operation consists of implementing changes of the patterns (fixtures) that are on the work tables, shown in figure 1; in this working station there are two such working tables.

Both workers take the fixture, that has two grips, and lift it, carrying it to the available rack and, following a prescribed sequence, when arriving to the rack, they place it and push it until it reaches the limit stop. Thereon, they take another devise, they pull it out of the shelf, they lift it also together and carry it to the other table, where they arrange it and then turn back to the rack to take another fixture (whose position and weight depends on what is expected in the process) and they repeat the action of pushing to raise it then and to move it to the table that has not yet a fixture, when they reach it, they place it. With this, the operation of loading and arranging devices on the tables is then completed.

The weights of these devices range from 10 kilograms, over 20 kilograms to maximum about 43 kilograms. This loading activity takes around two minutes per shift, and takes place at the beginning and at the end of the shift, representing 0.88 % of the programmed time of the working day.

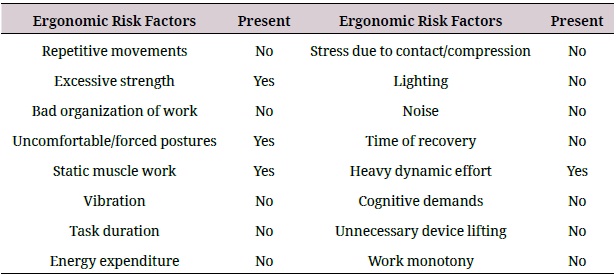

As it can be observed, the activity requires the use of relevant muscle strength to move, raise, carry and put down, adjusting, metal plaques of the fixture, both on the working tables and on the rack as it is detailed in table 1.

Identifying Risk Postures

Once the ergonomic risk factors present in the activity are determined, the analysis of these factors is performed through the different methods for assessing the associated ergonomic risk. In general, the main potential risk factors were identified: manual operation of loads and inadequate and non-neutral postures.

As it is represented bellow, the task is divided into three parts: 1) taking the fixture from the rack, 2) moving, carrying and placing the fixture on the work tables, and 3) moving the fixture to the rack. On this basis the activities are analyzed separately in order to determine which of them could represent for the workers the highest risk for musculoskeletal injuries.

The activities involving the part of taking the fixture from the rack were video-recorded, from this record 29 postures of interest were selected and analyzed using the owas method for studying which set of postures represent the highest risk for the workers.

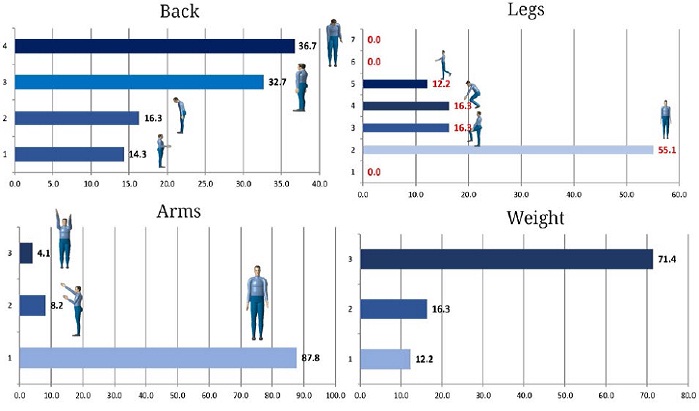

Likewise, studies for back, arms, legs and the weight the workers manipulate in this operation were conducted. A summary of the obtained information is shown in figure 2.

Assessment of the Groups of the Human Body in Risk

Based on this method, the 4th level activities —those that pose a greater risk— were selected as fundamental parts for starting the remaining analyses. Once the risk postures were identified, an evaluation through qec was carried out for identifying which groups of the human body were at greater risk.

Use of reba for Confirmation of Findings

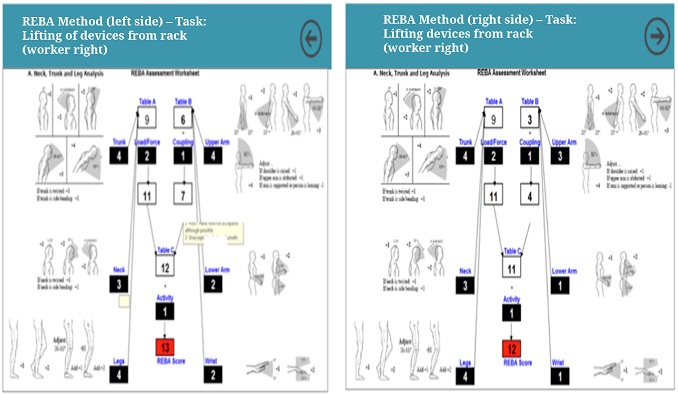

Subsequently, the postures detected through owas continued to be used to perform the reba analysis, and when the analysis of the postures that in owas reached risk level 5 was conducted, the reba results were confirmed, obtaining scores ranging between a minimum of 10 (the only yellow variable) and a maximum of 13 (red). Figure 3 shows the reba analysis implemented to the device lifting task by the workers.

Implementing the niosh Formula

In the case of lifting loads, the niosh formula was implemented with a worker who lifted the fixture and then, due to the technical limitations characteristic for the niosh formula for manually load lifting, an additional PM factor (for group lifting, in this case, by two persons) conform to iso 11228-1 was added (10).

Afterward, the same operation was studied, but changing the number of persons involved, as well as the kind of gage they manipulated.

Additional to these analyses, two tests were conducted using the 3DSSPP program (University of Michigan) for analysis of static posture efforts. It was observed that in this posture, a compressive effort of 8193 newtons is exerted in the low back and that, practically 0 % of population could perform this task without being exposed to an injury.

The free body diagram shows that, beside the lifting action, a displacement of a plate out of the rack is taking place, therefore, a friction force of metal to metal must be counterbalanced, thus worsening the activity: the action of pulling out in an unfavorable position, and, moreover, lifting suddenly from a risk position.

Finally, other complementing tools were used in order to assess risk associated to load manipulation. The previous format shows so-called safe zones.

Impact Assessment

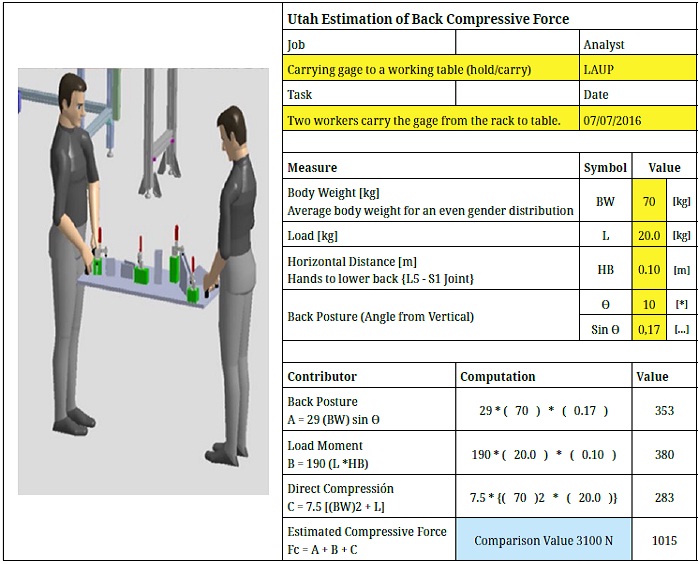

Concerning the second part of the task: moving, carrying and placing fixtures on the working tables, an analysis following the Utah Compressive Force Model was conducted in order to compare with the effect it has on the musculoskeletal system as it is shown in figure 4.

It was observed that the workers manipulating the load do not assume optimal postures for carrying it. This can contribute to the appearance of micro-traumatisms over time.

Besides, because of muscle weakness of the anterior and posterior lumbar zone, bone quality, age and possible injuries due to the performance of everyday activities of the worker, wearing of the lumbar spine could appear causing spondyloarthrosis.

Results

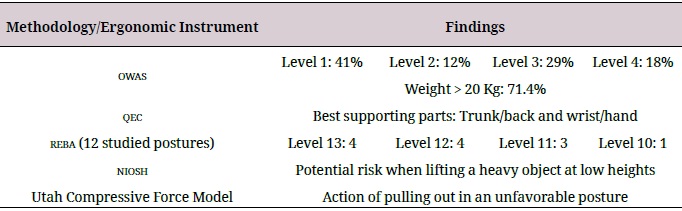

Once the ergonomic study of the quality process of a Mexican company of the automotive sector was completed, the main potential risk factors were identified, as it is shown in table 2.

Out of the studies conducted with the owas method, it was found that 41 % of the postures correspond to risk level 1; 12 % to level 2; 29 % to level 3; and finally, 18 % to risk level 4. Rotated back and bent knees represent 32.65 % and 36.73 %, respectively. As to arms, around 87 % of time they are beneath shoulder level, and concerning to the legs, beside 55 % corresponding to standing; to stand on one leg represents 16.3 %, the same as standing with bent knees. And finally, concerning the load weight, a weight over 20 kilograms in 71.4 % of times is manipulated.

With regard to the qec analysis, it should be stressed that as the fixture weight grows, the trunk/back score grows too, actually, manipulating 43 kilograms is the only item in the three tests in which the trunk registers the highest scores. And as the weight decreases, it decreases from 32, in the high zone, down to 24, in the moderate zone. Contrary to what it could be thought, according to what is shown in the qec method, the parts most sensitive to risk exposure are trunk/back and wrist/hand. These deviations in the wrists for manipulating the loads worsen when the arms are abducted to carry the object, thus performing a lifting movement that places higher pressure on the elbows and could require an extra effort on the lumbar zone of the spine.

In the reba analysis, out of twelve analyzed postures, four correspond to level 12, three to level 11, and a remaining one to level 10, indicating the risk level these postures and tasks have, that are worsened by their relation to the load.

The niosh indexes (individual lifting and lifting by two persons) yielded high results except when the load is equal to 10 kilograms. It should be noticed that the lifting task is associated with a potential risk since a heavy object is lifted to lower heights, but the lifting technique implemented by the workers was also observed, a fact that adds another factor to the risk of this task. What favors this activity is its low repetition, thus allowing that the activity is not performed with care or regarding the adequate lifting measures or the postural indications for spine postural hygiene.

In the analysis of the activity of taking the fixture from the rack it was found that, in this posture, a compressive effort of 8193 newtons in the low back was registered, vastly exceeding the limits established by niosh, and that virtually nobody could be able to perform this task without being exposed to an injury. Regarding the Utah Compressive Force Model, the free body diagram shows, beside the lifting action, a displacement of the plate out of the rack that requires counterbalancing the friction force of metal to metal; this worsens the activity: the action of pulling out in an unfavorable posture and, moreover, lifting in a sudden way and in a risk posture.

Discussion

Throughout history, ergonomic assessment technics have been developed. However, there is no technic that considers all aspects related to a task performed in a work center. These techniques are mostly centered on one or more ergonomic aspects and have validity only for certain assumptions in which they have been produced. One of these, the niosh lifting equation, is limited to loads carried with two hands, a duration not exceeding eight hours and the condition that the task is performed in an unrestrained environment (5, 11). The contribution of the present study is the combination of this technique with other ergonomic instruments in order to deepen the analysis of the studied task and even to validate the obtained results. Regarding the Ovako Working Posture Analysis System (owas), there are studies in areas of metallurgy, packaging, and rubber proving that category 4 activities could represent a musculoskeletal disorder in back and legs (6, 12,13,14). In the present research the latter is proved and it is noteworthy that the situation worsens with inadequate postures, repetitive movements, manual loading, or inadequate hand positions like the one performed in the inspection activity of the studied work station. On its part, the Quick Exposure Check has been implemented for assessing musculoskeletal disorders in different human activities like motorcycling, agriculture or health caring (15, 16, 17). In industrial terms, a correlation between efficacy and qec results has been proposed, with a negative outcome, so that identifying excessive force, uncomfortable or forced postures, static muscle work, and heavy dynamic effort in inspection works provides an initial scenario for developing programs designed to decrease risk factors (18). For assessing upper and lower limbs the rula (Rapid Upper Limb Assessment) and reba (Rapid Entire Body Assessment) methods are implemented interchangeably, aiming at validating the results obtained by one of them, a situation proved in a study carried out in Pakistan with workers of clothing manufactures (19). The approach of this work proposes validating results between reba techniques and the niosh lifting equation with their corresponding restrictions. The work requests and the current conditions in which male workers perform the analyzed inspection activity trigger strongly the possibility of suffering a back injury, a situation that, in similar working conditions experienced by women in the brick production in India (20). This implies that gender is not a determining factor for the appearance of musculoskeletal disorders. Likewise, the Three-Dimensional Static Strength Prediction Program has been used for studying biomechanical loads in the assistance of wheelchair users and the low back compressive force in pushing actions by bus drivers (21). A similar situation is observed in activities of uploading and downloading of fixtures from the racks, beside the negative effect in the joints of both the upper and the lower libs.

Finally, the authors of this article point out that ergonomic studies traditionally use one or two instruments for generating conclusions, a paradigm that is not completely wrong. However, implementing over three instruments of ergonomic risk assessment allows broadening the analysis spectrum and, with it, reassuring the validity of results and a bettering in decision making in order to reduce the risks they represent (22).

The implemented instruments for ergonomic analysis allow identifying the risks present in the studied inspection task. This task, if not performed with the necessary care and for its own characteristics, could even produce —in certain individuals and very specific conditions— herniated disk due to faulty postures in manipulating loads.

During the manipulation of loads, the back is not straight, it bends forward, and two lumbar turns are made, one for taking the load, the other for pulling it. Moreover, individuals do not completely return to an ideal posture and start then with the load carrying activity. As expected, over the years, micro-traumatisms as a result of repetitive actions can be caused. It is suggested to create a general strengthening program for arms, legs and lumbar anterior and posterior zones with the aim of preventing such injuries. This program should be individualized since the exercise should be adapted to the characteristics of each worker and not the worker to the exercise. Lastly, awareness to all organization personnel with training in manual handling of loads and spine hygiene is suggested.

Disclaimer

The authors have no conflict of interests in this study. Likewise, they affirm that life, health, dignity, integrity, right to self-determination, intimacy, and data protection of the participants in the research were protected.

Authors' contributions

Authors' contributions

All authors have contributed to the argumentation and the writing of this study.

References

1.Secretaría del Trabajo y Previsión Social. Subsecretaría de Empleo y Productividad laboral [internet]. 2018. Disponible en: Información Laboral: https://www.siel.stps.gob.mx:304/perfiles/perfiles_detallado/perfil_puebla.pdf

2.Nawi NSM, Deros BM, Nordin N. Assessment of oil palm fresh fruit bunches harvesters working postures using reba. Advanced Engineering Forum. 2013;(10):122-7. Doi: 10.4028/www.scientific.net/AEF.10.122

3.Paunescu R. Tools and techniques for improving the modular fixture design in Autodesk Inventor. Journal of Ind Design and Eng Graphics. 2015;(10):37-42.

4.Rwamamara R, Simonsson P. Self-compacting concrete used for construction work environment sustainability. Journal of Civil Eng and Management. 2012;(18)5:724-34. Doi: https://doi.org/10.3846/13923730.2012.723399

5.Kamarudin NH, Ahmad SA, Hassan MK, Yusuff RM, Md Dawal SZ. A review of the niosh Lifting Equation and Ergonomics Analysis. Advanced Eng Forum. 2013;(10):214-9. Doi: https://doi.org/10.4028/www.scientific.net/AEF.10.214

6.Lasota AM. A reba-based analysis of packers workload: A case study. LogForum. 2014;(10):87-95.

7.Maldonado-Macías A, Realyvásquez A, Hernández JL, García-Alcaraz J. Ergonomic assessment for the task of repairing computers in a manufacturing company: A case study. Work. 2015;(52):393-405. Doi: 10.3233/WOR-152118

8.Xu Y, Cheng ASK. An onsite ergonomics assessment for risk of work-related musculoskeletal disorders among cooks in a Chinese restaurant. Work. 2014;(48):239-545. Doi: 10.3233/WOR-131805

9.Corella F, Jiménez R, Meza N, Borz S. The use of owas in forest operations postural assessment: advantages and limitations. Bulletin of the Transilvania University of Brasov. 2015;8(57) No. 2.

10.ISO. 2003. ISO 11228-1:2003 Ergonomics – Manual handling- Part I: Lifting and carrying.

11.Mirka GA, Kelaher DP, Nay T, Lawrence BM. Continuous assessment of back stress (CABS): A new method to quantify low-back stress in jobs with variable biomechanical demands. Human Factors. Summer. 2000;(42):209-25. Doi: 10.1518/001872000779656525

12.Sadeghi F, Assilian H, Barati L. Analysis of working postures in iron and steel industry workers using computerized owas method. J of Kermanshah University of Medical Sciences. 2007;(11).

13.Velázquez S, Valderrama S, Giraldo D. Ergonomic assessment of natural rubber processing in plantations and small enterprises. Ingeniería y Competitividad. 2016;(18):233-46.

14.Hoy D, March L, Brooks P, Blyth F, Woolf A, Bain C, et al. The global burden of low back pain: estimates from the Global Burden of Disease 2010 study. Ann Rheum Dis. 2014;(73):968-974. Doi: 10.1136/annrheumdis-2013-204428

15.Ramasamy S, Adalarasu K, Trupti NP. Evaluation of driving-related musculoskeletal disorders in motorbike riders using Quick Exposure Check. Biomedical Research. 2017;28(5):1962-8.

16.Sukadarin EH, Deros BM, Ghani JA, Ismail AR, Mokhtar MM, Mohamad D. Investigation of ergonomics risk factors for musculoskeletal disorders among oil palm workers using Quick Exposure Check (qec). Advanced Eng Forum. 2013;(10):103-9. Doi: 10.4028/www.scientific.net/AEF.10.103

17.Ericsson P, Bjorklund M, Wahlstrom J. Exposure assessment in different occupational groups at a hospital using Quick Exposure Check (QEC) – A pilot study. Work. 2012;(41):5718-5720. Doi: 10.3233/WOR-2012-0929-5718

18.Yarahmadi R, Abarashi F, Solhi M, Haghani H. Understanding the role of response efficiency on reducing ergonomic risk factors in a manufacturing industry in Sabzevar. ioh. 2013;(10):36-42.

19.Sha ZA, Amjad A, Ashraf M, Mushtaq F, Sheikh I. Ergonomic risk factors for workers in garments manufacturing – A case study from Pakistan. Proceedings – International Conference on Industrial Engineering and Operations Management; Kuala Lumpur, Malaysia. IEOM Forum; 2016.

20.Das B. An evaluation of low back pain among female brick field workers of West Bengal, India. Environ Health Prev Med. 2015;(20):360-8. Doi: 10.1007/s12199-015-0476-0

21.Bareria P, Shin G. Assisting wheelchair users on bus ramps: A potential cause of low back injury among bus drivers. Internat Industrial Eng. 2014;21(5):243-52.

22.Shanahan CJ, Vi P, Salas EA, Reider VL, Hochman LML, Moore AE. A comparison of rula, reba and Strain Index to four psychophysical scales in the assessment of non-fixed work. Work. 2013;(45):367-78. Doi: 10.3233/WOR-121540

Author notes

* Corresponding author: luis.cuautle@upaep.mx